Views: 0 Author: Site Editor Publish Time: 2023-10-31 Origin: Site

Wire Rope: An Introduction to its Construction, Applications, and Metal Types

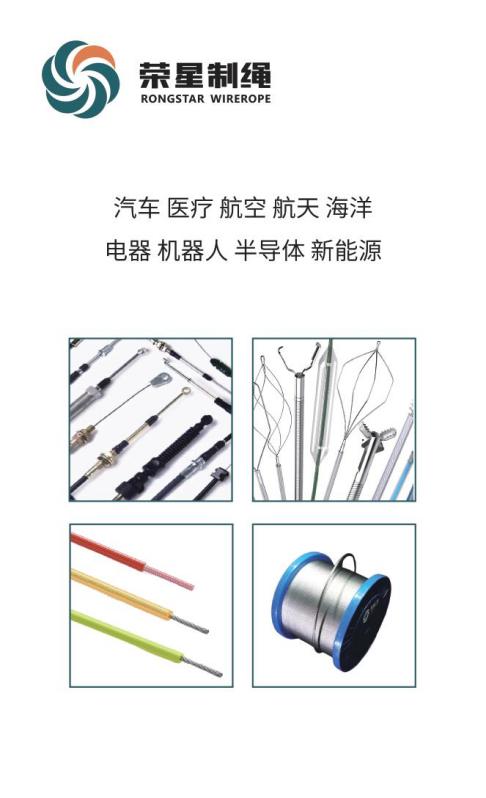

Wire rope is a flexible and multipurpose tool extensively utilized for demanding and high-strength lifting tasks. It comprises numerous components that work in harmony, including 150 outer strands intricately intertwined and upheld by a pliable core.

A crucial aspect of wire rope design is the required clearance between strands, allowing each strand to freely move and adjust when the rope is bent. This unique characteristic sets wire rope apart from solid wires and other cable forms.

Wire rope is composed of three fundamental components: wires, strands, and a core, which are intertwined to form the rope.

Wires: The basic building blocks of wire rope are the wires used for configuration, shaping, and ropemaking. Preferred choices include steel wires, stainless steel wires, and galvanized wires, followed by aluminum, nickel alloys, bronze, copper, and titanium. The selection of wires depends on the intended use of the wire rope, with strength, flexibility, and wear resistance being the primary determining factors.

Galvanized Steel: Galvanized steel wires have a zinc coating on their surface to prevent corrosion and serve as an economical alternative to stainless steel.

Stainless Steel: Stainless steel wire ropes exhibit the basic characteristics of galvanized and regular steel wire ropes while offering additional benefits such as excellent corrosion resistance, making them suitable for applications in harsh environments.

The strands, also known as outer bundles, are composed of multiple wires twisted together in a specific pattern. The number of wires per strand and the pattern of twisting contribute to the strength and flexibility of the wire rope.

The core provides support and stability to the wire rope, enhancing its load-bearing capacity and overall durability. Common core types include fiber cores (natural or synthetic) and independent wire rope cores (IWRC), each offering distinct advantages for different applications.

Wire rope is a complex and reliable tool used in various industries for heavy lifting and extreme operations. Understanding its construction, metal types, and components is essential for selecting the right wire rope for specific applications, ensuring safety and optimal performance.